Northern White Sand/Wisconsin Operations Technical Data

Our Wisconsin sand operations (Augusta, Blair, Whitehall, Wyeville) are unit-train-capable facilities with total annual capacity of 10.4 million tons of premium Northern White frac sand. Sourced from a Pleistocene alluvial flow deposit of reworked, quartz-rich, Cambrian period sandstones, our Wisconsin natural proppants are geologically and texturally mature, exhibiting exceptional purity, shape, strength and conductivity.

WISCONSIN FACILITIES

Augusta, Blair, Whitehall, Wyeville

10.4 Million TPY Capacity

84,000 Ton Silo Storage

Union Pacific and Canadian

National Railroad Origin

Download To Read Later

Northern White Primary Proppant Grades

| Typical Properties |

20/40

|

30/50

|

40/70

|

100 M

|

| 13503-2/API RP 19C |

-20+40 |

-30+50 |

-40+70 |

-50+140 |

| Sect. 6 “Sieve Analysis” |

| 16 | 0.0 | | 20 | 3.6 | | 25 | 20.6 | | 30 | 33.9 | | 35 | 33.5 | | 40 | 6.8 | | 50 | 1.2 | | Pan | 0.3 |

|

| 20 | 0.0 | | 30 | 1.5 | | 35 | 19.0 | | 40 | 44.4 | | 45 | 25.7 | | 50 | 5.8 | | 70 | 2.6 | | Pan | 0.4 |

|

| 30 | 0.0 | | 40 | 1.9 | | 45 | 21.7 | | 50 | 36.3 | | 60 | 26.7 | | 70 | 9.4 | | 100 | 3.5 | | Pan | 0.1 |

|

| 50 | 0.0 | | 70 | 35.7 | | 80 | 22.6 | | 100 | 18.5 | | 120 | 11.5 | | 140 | 5.9 | | 200 | 4.2 | | Pan | 0.2 |

|

| Percent in Size (API/ISO Standard) |

> 90% |

> 90% |

> 90% |

> 90% |

| Mean Diameter (mm) |

0.620 mm |

0.424 mm |

0.304 mm |

0.202 mm |

| Median Diameter (mm) |

0.606 mm |

0.416 mm |

0.297 mm |

0.196 mm |

| Sect. 7 "Shape" |

|

|

|

|

| Roundness |

0.8 |

0.7 |

0.7 |

0.7 |

| Sphericity |

0.8 |

0.7 |

0.7 |

0.7 |

| Sect. 8 "Acid Solubility" |

|

|

|

|

| 12:3 HCI/HF @ 150° F |

< 2% |

< 2% |

< 2% |

< 2% |

| Sect. 9 “Turbidity” |

|

|

|

|

| NTU |

< 250 |

< 250 |

< 250 |

< 250 |

| Sect. 10 “Proppant Density” |

|

|

|

|

| Bulk (g/cm3) |

1.56 |

1.53 |

1.51 |

1.50 |

| Bulk (lb/ft3) |

97.22 |

95.64 |

94.35 |

93.78 |

| Apparent [Oil] (g/cm3) |

2.64 |

2.63 |

2.64 |

2.63 |

| Settling Rate (ft/min) |

61.84 |

61.84 |

61.84 |

61.84 |

| Sect. 11 “Crush Resistance” |

|

|

|

|

| K Value |

6K–7K |

8K–10K |

9K–11K |

10K–14K |

| Loss at K Value |

7.68% @ 6,000 |

9.22% @ 8,000 |

8.65% @ 9,000 |

8.70% @ 10,000 |

| |

9.12% @ 7,000 |

9.38% @ 10,000 |

9.20% @ 11,000 |

9.00% @ 14,000 |

| Typical Properties |

30/50

|

| 13503-2/API RP 19C |

-30+50 |

| Sect. 6 “Sieve Analysis” |

| 20 | 0.0 | | 30 | 1.5 | | 35 | 19.0 | | 40 | 44.4 | | 45 | 25.7 | | 50 | 5.8 | | 70 | 2.6 | | Pan | 0.4 |

|

| Percent in Size (API/ISO Standard) |

> 90% |

| Mean Diameter (mm) |

0.424 mm |

| Median Diameter (mm) |

0.416 mm |

| Sect. 7 "Shape" |

|

| Roundness |

0.7 |

| Sphericity |

0.7 |

| Sect. 8 "Acid Solubility" |

|

| 12:3 HCI/HF @ 150° F |

< 2% |

| Sect. 9 “Turbidity” |

|

| NTU |

< 250 |

| Sect. 10 “Proppant Density” |

|

| Bulk (g/cm3) |

1.53 |

| Bulk (lb/ft3) |

95.64 |

| Apparent [Oil] (g/cm3) |

2.63 |

| Settling Rate (ft/min) |

61.84 |

| Sect. 11 “Crush Resistance” |

|

| K Value |

8K–10K |

| Loss at K Value |

9.22% @ 8,000 |

| |

9.38% @ 10,000 |

| Typical Properties |

40/70

|

| 13503-2/API RP 19C |

-40+70 |

| Sect. 6 “Sieve Analysis” |

| 30 | 0.0 | | 40 | 1.9 | | 45 | 21.7 | | 50 | 36.3 | | 60 | 26.7 | | 70 | 9.4 | | 100 | 3.5 | | Pan | 0.1 |

|

| Percent in Size (API/ISO Standard) |

> 90% |

| Mean Diameter (mm) |

0.304 mm |

| Median Diameter (mm) |

0.297 mm |

| Sect. 7 "Shape" |

|

| Roundness |

0.7 |

| Sphericity |

0.7 |

| Sect. 8 "Acid Solubility" |

|

| 12:3 HCI/HF @ 150° F |

< 2% |

| Sect. 9 “Turbidity” |

|

| NTU |

< 250 |

| Sect. 10 “Proppant Density” |

|

| Bulk (g/cm3) |

1.51 |

| Bulk (lb/ft3) |

94.35 |

| Apparent [Oil] (g/cm3) |

2.64 |

| Settling Rate (ft/min) |

61.84 |

| Sect. 11 “Crush Resistance” |

|

| K Value |

9K–11K |

| Loss at K Value |

8.65% @ 9,000 |

| |

9.20% @ 11,000 |

| Typical Properties |

100 M

|

| 13503-2/API RP 19C |

-50+140 |

| Sect. 6 “Sieve Analysis” |

| 50 | 0.0 | | 70 | 35.7 | | 80 | 22.6 | | 100 | 18.5 | | 120 | 11.5 | | 140 | 5.9 | | 200 | 4.2 | | Pan | 0.2 |

|

| Percent in Size (API/ISO Standard) |

> 90% |

| Mean Diameter (mm) |

0.202 mm |

| Median Diameter (mm) |

0.196 mm |

| Sect. 7 "Shape" |

|

| Roundness |

0.7 |

| Sphericity |

0.7 |

| Sect. 8 "Acid Solubility" |

|

| 12:3 HCI/HF @ 150° F |

< 2% |

| Sect. 9 “Turbidity” |

|

| NTU |

< 250 |

| Sect. 10 “Proppant Density” |

|

| Bulk (g/cm3) |

1.50 |

| Bulk (lb/ft3) |

93.78 |

| Apparent [Oil] (g/cm3) |

2.63 |

| Settling Rate (ft/min) |

61.84 |

| Sect. 11 “Crush Resistance” |

|

| K Value |

10K–14K |

| Loss at K Value |

8.70% @ 10,000 |

| |

9.00% @ 14,000 |

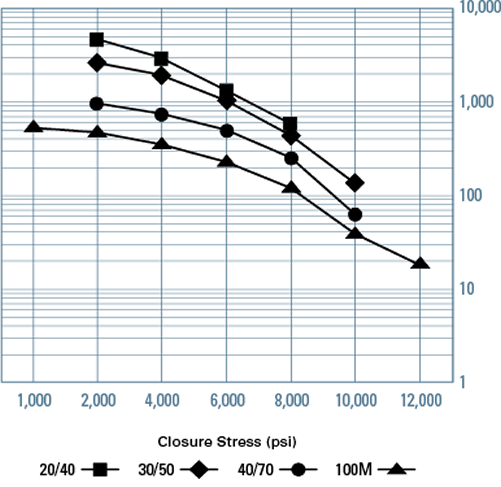

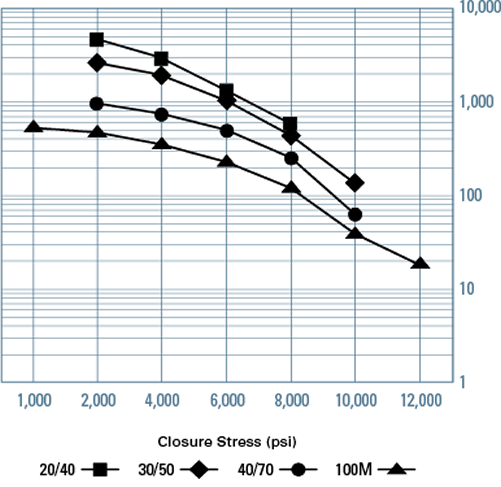

Conductivity (md-ft)

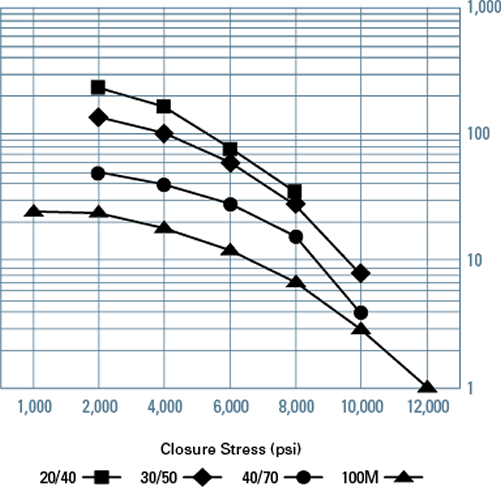

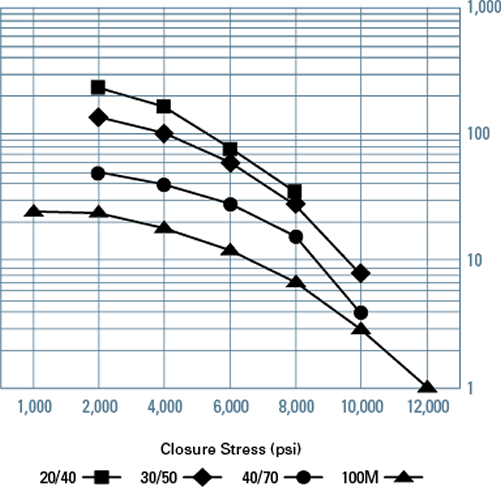

Permeability(darcy)

Long-Term Conductivity and Permeability 2% KCL Between Ohio Sandstone at 150°F for 50 hr Per Stress

| Conductivity (md-ft) |

| Stress (psi) |

20/40 |

30/50 |

40/70 |

100 M |

| 1,000 |

|

|

|

528 |

| 2,000 |

4,376 |

2,574 |

1,001 |

474 |

| 4,000 |

3,035 |

1,910 |

783 |

352 |

| 6,000 |

1,362 |

1,034 |

523 |

231 |

| 8,000 |

570 |

443 |

262 |

122 |

| 10,000 |

|

138 |

68 |

39 |

| 12,000 |

|

|

|

18 |

| Permeability (darcy) |

| Stress (psi) |

20/40 |

30/50 |

40/70 |

100 M |

| 1,000 |

|

|

|

25 |

| 2,000 |

229 |

138 |

53 |

24 |

| 4,000 |

165 |

106 |

42 |

18 |

| 6,000 |

78 |

60 |

29 |

12 |

| 8,000 |

34 |

27 |

16 |

7 |

| 10,000 |

|

8 |

4 |

3 |

| 12,000 |

|

|

|

1 |

Disclosure: Material physical and performance properties are measured using recognized industry procedures and facilities. Average values may apply. Hi-Crush Inc. and its affiliates make no warranty for their products, express or implied. We recommend you confirm all properties and suitability for use. All products are sold under Hi-Crush Inc. and its affiliates applicable standard terms and conditions of sale.

Silica Sand Danger: This product has been classified following the Globally Harmonized System (GHS) of Classifying and Labeling Chemicals Criteria as a Category 1A Carcinogen, Category 1 Specific Target Organ Toxicity (following repeated exposures), and Category 2B Eye Irritant. For Industrial Use Only. Avoid creating dust when handling, using or storing product. Do not breathe dust. Prolonged exposure to dust may cause delayed lung injury (silicosis). Read Material Safety Data Sheet before using and follow OSHA or other applicable health and safety standards for crystalline silica/quartz.